WHY INLINE?

Inline offers a fully automated and integrated inspection station for a wide range of metallic production facilities. Inline runs at the speed of your production pace.

00 High production rates on a fast in-line inspections.

01 Integration between mechanical, HW, SW and factory.

02 Integration between mechanical, HW, SW and factory.

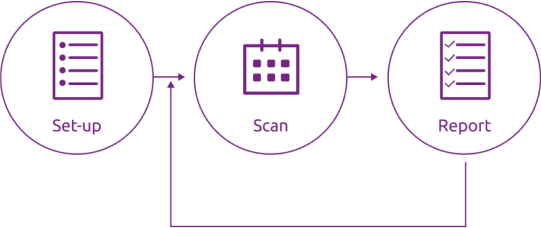

HOW DOES IT WORK

For manufacturers that need to perform quality inspections on their high speed production lines, and require the highest level of reliably to minimize downtime, Inline is the answer. Inline is the leading automated NDT system for continuous production lines that uses high performance phased array UT technology. Thanks to its reliability and full integration in the factory, Inline systems are used around the world for the production of all types of tubes and bars.

Benefits

- Fast and reliable inspection

- Excellent coupling in all situations

- Real-time visualization of UT-scan

- Supported by continuous innovations

- Adaptable to all tube dimensions and bars up to 250 mm

- Suitable for Tubes with Seamless, welded, ERW or L-SAW

- Suitable for Round, Square and Hexagonal bars of Al, Ti, Steel alloys

- Suitable for non-straight bars/tubes/welds

- Easy system set-up

- Very Robust with Low Maintenance

Related Products

Bacus

BACUS provides a powerful and flexible system for automated immersion inspection of metallic and composite components.

MORE INFORMATION?

Use our wide range of ultrasonic and Eddy current products and systems: instrument offering different levels of performance, probes, software, development of techniques.

Blog

Latest insights and highlights

Array