WHY BACUS?

BACUS provides a powerful and flexible system for automated immersion inspection of metallic and composite components. A scalable system that can be dimensioned to any part, just add water.

HOW DOES IT WORK

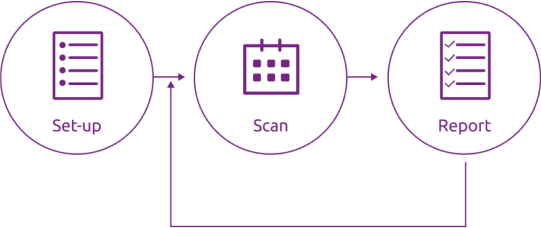

BACUS is an automated tank for the immersion inspection of a wide variety of aerospace and industrial components. It consists of a tank and gantry with a manipulator and optional component turntable or rotators (up to 8 automated axes configurable). Scan routines can range from simple 2D to 3D complex trajectories.

BACUS is suited for both through transmission and pulse-echo techniques with conventional or phased array electronics. Based on TECNATOM proprietary technology it enables a seamless and efficient inspection process. In short, BACUS means productive and reliable immersion inspections.

Benefits

PRODUCTIVE

- High-performance TECNATOM SONIA UT electronics.

- Phased Array and Multichannel inspection.

- Powerful TECNATOM software evaluation tools.

- Low Maintenance.

- Remote and local support.

FLEXIBLE

- Wide variety of inspected components such as engine disks, turbine shafts, stiffeners, plates, billets, composites or bearings.

- Up to 8 automated axis: 3 linear, 3 for manipulator, and 2 for component rotation (turntable or rollers).

- 2.5D & 3D inspection with CAD file import feature Ample range of frequencies including HF.

- Design customizable to customer specification.

INTEGRATED

- Integrated TECNATOM software suite for the complete inspection process.

- Seamless compatibility of all components.

- Connection to factory MES and databases.

MULTIPLE NDT METHODS

- High quality industrial components of renowned suppliers.

- Heavy-duty proven system.

- TECNATOM proprietary technology.

- High mechanical repeatability.

- More than 20 references worldwide.

MORE INFORMATION?

Use our wide range of ultrasonic and Eddy current products and systems: instrument offering different levels of performance, probes, software, development of techniques.

Blog

Latest insights and highlights

Array