WHY Wiipa?

WiiPA provides a powerful and flexible system for manual inspections of complex components. WiiPA puts quality control at your fingertips. WiiPA will help you to create manufacturing quality records.

00 Semi-permanent installation

01 No Civil Works required

02 Overhead structure, efficient use of floor space

03 Scalable to any size. Ideal as a back-up for other systems

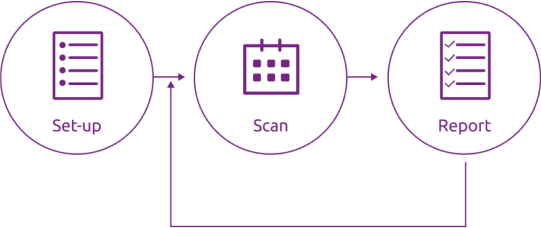

HOW DOES IT WORK

WiiPA is a wireless integrated semi-automatic inspection system, based on 3D motion capture by Infrared cameras that accurately track and register the position of the NDT probe in real time.

The system is especially suited for Pulse-Echo Phased Array Inspections.The WiiPA system is Tecnatom’s versatile solution for systems that need to cover a wide range of flat, curved and complex contoured parts. WiiPA is fast and easy to use: an excellent solution for inspections that require a traceable C-scan record.

Benefits

FAST INSPECTION

- Easy Set-up and Calibration

- SONIA Phased Array electronics

- Motion Capture for Accurate Probe tracking

FLEXIBLE

- No mechanical encoders

- No limit to cell size or complex part geometry

- Fixed installation or portable system

- Available for other NDT methods

USER FRIENDLY

- Pre-configuration of the Complete Process

- Absolute freedom of movement in 3D

- Scanning works like using a paintbrush (touching up of uncovered spots “on the go”)

- Realtime visualization of the complete C-scan through Augmented Reality

MULTIPLE NDT METHODS

- Traceable C-scan register

- Full compliance with industry standards

- Connection to factory MES

Related Products

Taurus

BACUS provides a powerful and flexible system for automated immersion inspection of metallic and composite components.

MORE INFORMATION?

Use our wide range of ultrasonic and Eddy current products and systems: instrument offering different levels of performance, probes, software, development of techniques.

Other Solutions

Blog

Latest insights and highlights

Array